The role of the Equator inspection system in modern production processes

RENISHAW

Pad. 9 stand C15

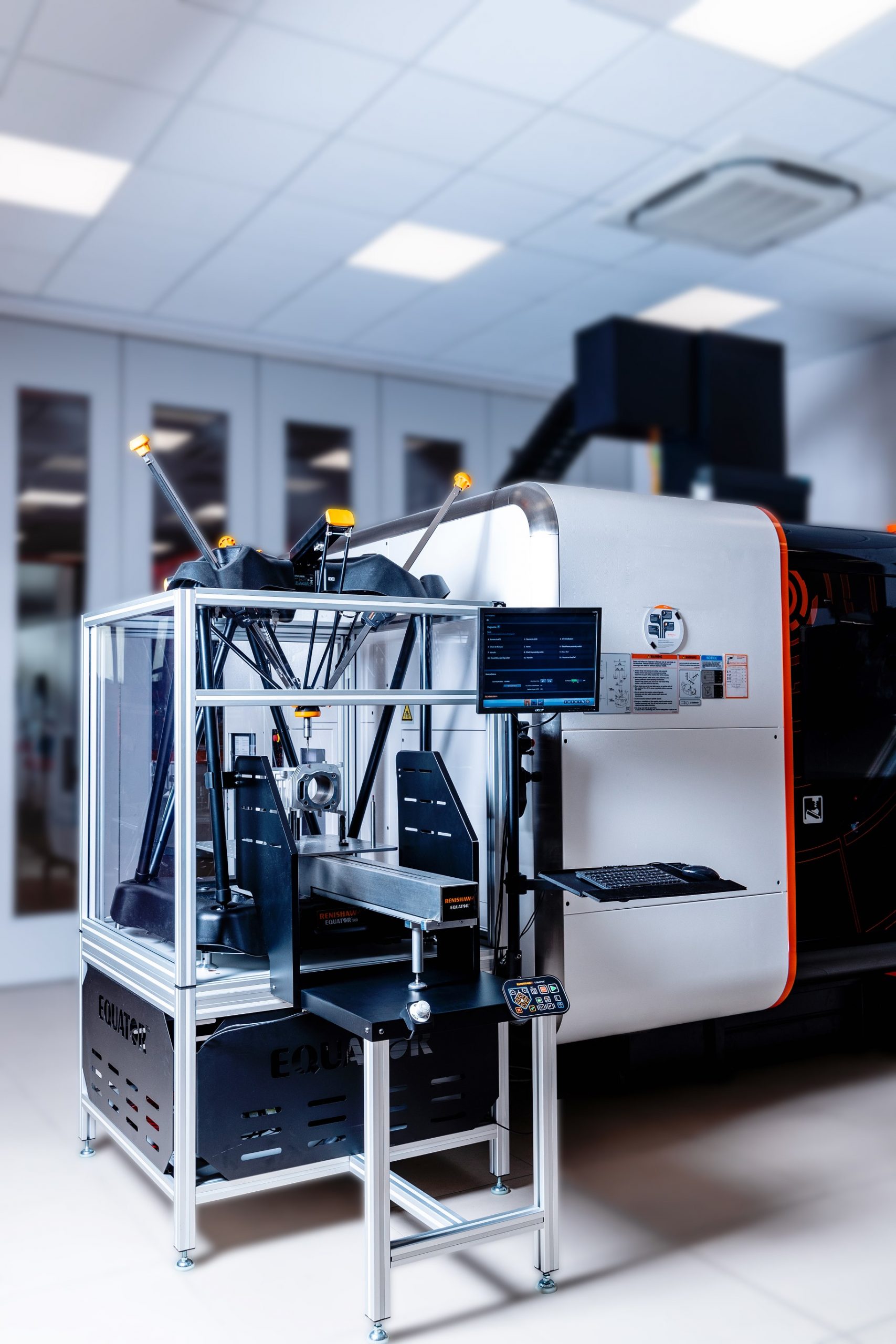

Renishaw, the leading manufacturer of metrology systems, will demonstrate how its innovative Equator solution can help optimize manufacturing operations and increase the sustainability of part design and production processes.

The caliber Equator will be one of the protagonists of the event, with demonstrations that will highlight the originality of its design and its operation, characteristics that have made it very popular among professionals around the world.

Equator functionality: The Equator system is a fast comparative gauge that inspects medium to large volumes of machined parts in key applications in various industries, such as vehicle transmission components and aircraft landing systems.

The gauge is very fast, repeatable and versatile and has been specially developed for use in the workshop.

The Equator system is capable of operating at temperatures ranging from 5 ºC to 50 ºC, can withstand humidity levels of up to 80% and has been optimized for loading workpieces via robots or shuttle systems. Its configuration simplifies communication between the system and a number of work cell devices and allows it to be easily integrated into an automation cell, ensuring significant cycle time reduction and increased productivity.

In addition, by introducing a flexible inspection system close to the production point, multiple machining operations can be validated and process control automation and tool corrector management improved. All this increases confidence in the quality of the final product.

For more information on new Renishaw solutions for process automation to improve productivity and sustainability visit BI-MU 2024 from 9 to 12 October.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.