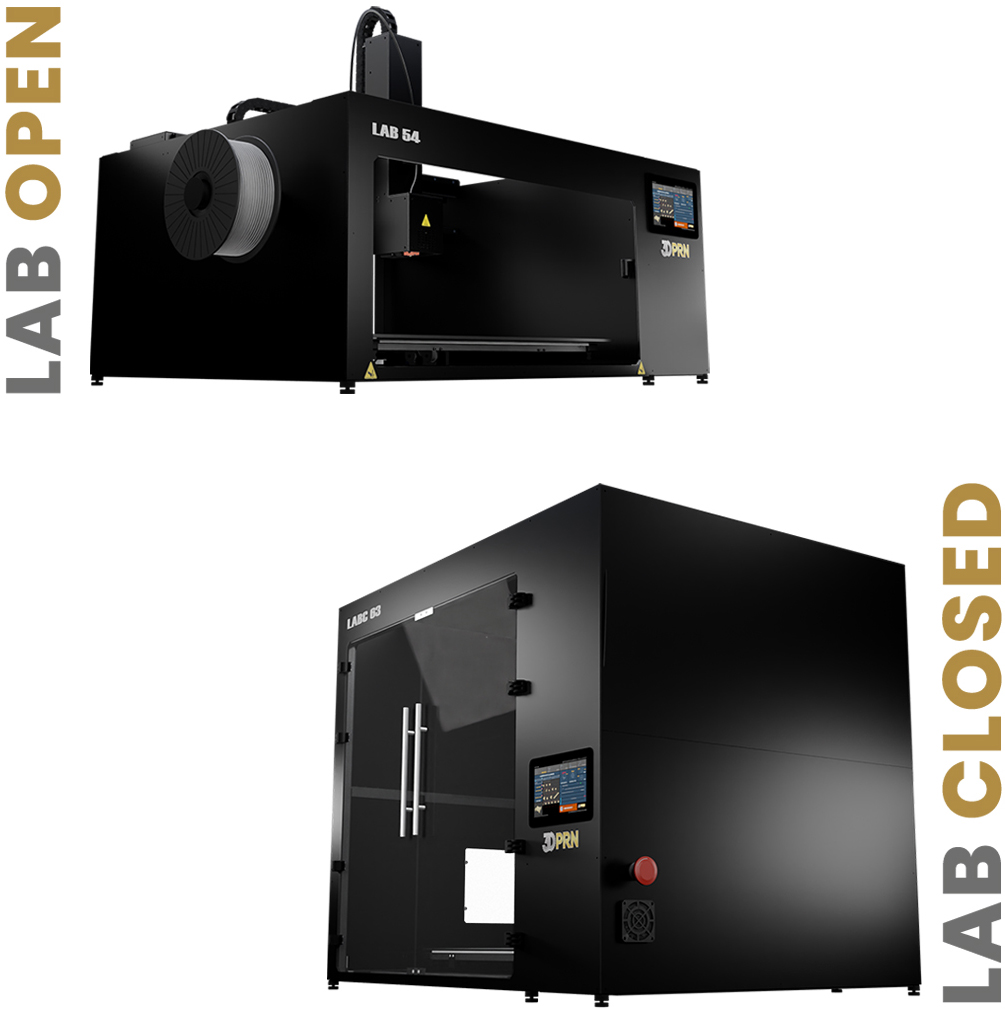

Professional 3D Printers

3DPRN – TIPS

Pad. 15 stand G29

For over thirty years in the IT sector, TIPS S.r.l.u. has been involved in software development and since 2012 in the production of 3D printers under the 3DPRN brand.

With 3DPRN, solutions are proposed for the company that wants to create prototypes, produce functional products, small series with excellent quality and dimensional precision due to the high technological hardware content and proprietary slicing software development.

All this has allowed us to have total control between hardware and software, allowing us to introduce innovative technological solutions. First of all, our printing and grinding system (X2 Mill) with automatic tool change. Once printed, this system allows us to refine, center the holes and reduce the tolerance using a splindle on an independent axis, all managed automatically by our slicing software. To continue, closed loop motors have been introduced at the hardware level, magnetic lines for centesimal calibration of the 3D printer, double-stage extruders for optimal management of extrusion temperatures, automatic calibration and management of extrusion pressure, etc. While the constant development of the software allows us to create features such as Precise Z to have the height of the precise and not approximate object, the height of the dynamic layers for the internal parts to reduce the production times of the object, advanced supports to use less material and time, internal reinforcements to increase the resistance of objects, etc…

We are currently the only ones to offer UP-GRADE of the printer; therefore, hardware and software updates can be made over time. The over thirty years of experience of 3DPRN technicians is a guarantee of the efficiency and completeness of the products.

3DPRN has always offered only products made in-house, guaranteeing complete and adequate after sales assistance.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.