Innovative online sleeves and rod configurator

MBO OSSWALD

Pad. 13 stand B54

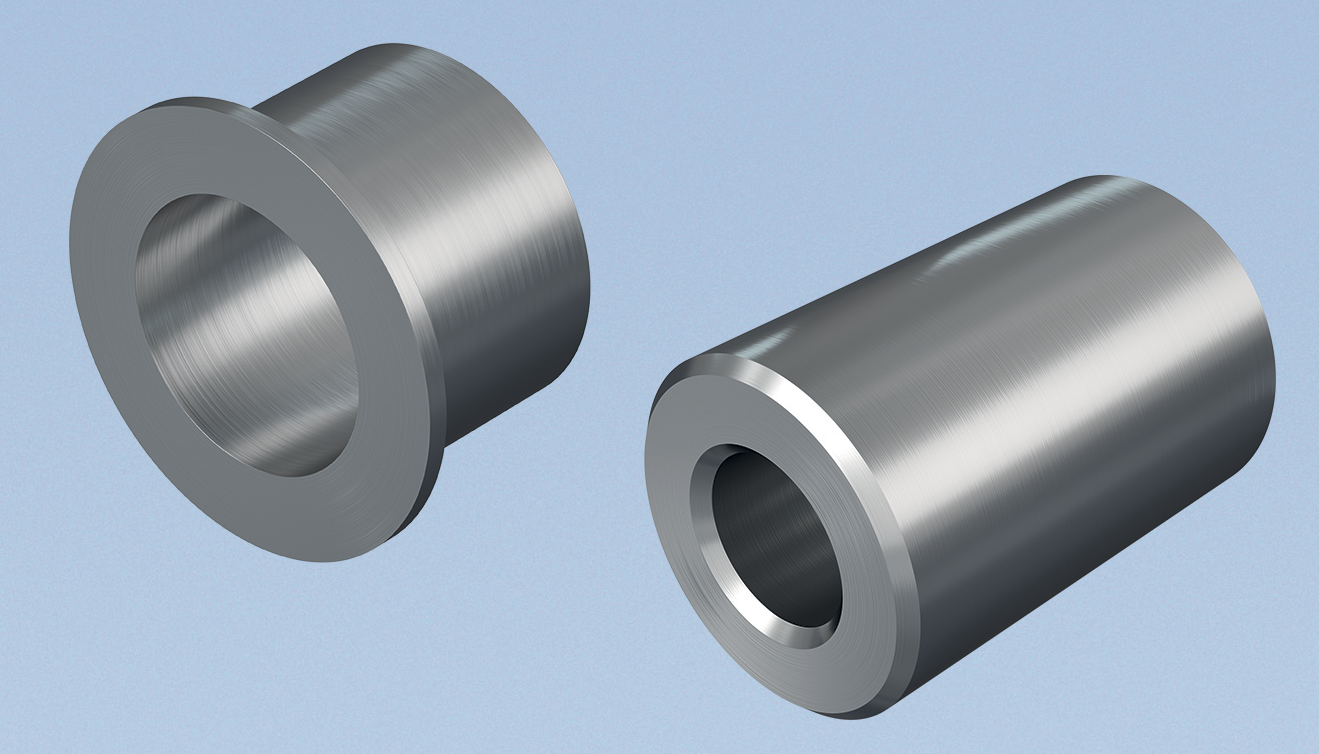

mbo Osswald is setting new standards in the world of linking technology with its latest online tool: The innovative sleeves configurator. This tool was developed to design individual parts precisely and in line with requirements and is suitable for use in very many different industry applications. Sleeves are well known as versatile components and are vital when precise spacings have to be adhered to in complex engineering designs. Sleeves are also often referred to as spacers, spacing rings, spacer tubes, bushes or distance rings.

The sleeves configurator is an intuitive, easy-to-operate, user-friendly platform that allows users to adapt sleeves to their own individual specifications and order the corresponding parts. What makes this digital tool so special is its transparency: Users see detailed information about every sleeve characteristic, including product details, a 3D model, technical drawings, test certificates, an express manufacturing option and dynamic price specifications.

Users can choose from a wide range of characteristics, including material, surface properties, shaft diameter, length, collar and wall thickness. When the user has chosen the required specifications, the configurator immediately provides detailed information about the part, including price, delivery time, a sketch and 3D model. Pricing is flexible and scaled in the light of the ordered quantity and users have full control over configuration and costs.

With this innovative configurator, mbo Osswald is extending its range of services and giving users even greater freedom in the design of their parts. With its many years of experience in the manufacture of turned parts, mbo Osswald is able to offer bespoke solutions for parts that go beyond the capabilities of the configurator. The mbo Osswald sleeves configurator therefore greatly enhances the possibilities for customer-specific parts design and emphasises the company’s commitment to an innovative, customer-oriented approach.

About mbo Osswald

mbo Osswald is a leading supplier of linking technology. At the Kuelsheim-Steinbach site, 70 employees manufacture more than 50,000 standard parts and are specialists in the production of individual drawing parts to meet specific customer requirements.

Portfolio:

Standard parts: Clevises, clevis joints, bolts, retainers, angle joints, ball sockets, ball studs, axial joints, rod ends, pivoting bearings, knuckle eyes, cardan joints, machine elements.

In the technically demanding world of linking technology, our company is taking customer interaction to a new level: With the introduction of the innovative rod end configurator, specially developed for DIN ISO 12240-4 (DIN 648), we are optimising the selection of rod ends. This online tool offers a fast, precise and customised selection of components and is therefore extremely helpful for a wide range of applications in different industries.

The rod end configurator presents an intuitive, user-friendly platform that allows users to select and directly order rod ends according to individual specifications. A key feature of this digital tool is its transparency: Users immediately receive detailed information on every feature of the rod end, including availability, price, delivery time, product details, 3D model and technical drawing, as well as additional information on Substance of Very High Concern (SVHC) or Product Carbon Footprint (PCF).

Users can choose from a wide range of options, including size, dimensional series, maintenance type, material or thread. Individual requirements for load rating, speed or temperature can also be taken into account, as can optional threaded bolts or sealings. Once the desired properties have been specified, the configurator immediately provides all relevant information on the component. The pricing adapts dynamically to the desired quantity, giving users complete control over the costs.

This innovative tool enables us to expand our range and strengthen our customers’ ability to design their own components. For more complex requirements that go beyond the standard options of the configurator, we continue to offer customised solutions as an experienced manufacturer in metal processing. The rod end configurator sets new standards in customised component design and reinforces our commitment to innovation and customer focus.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.