Ballscrews and Linear guideways

PRECISION MOTION INDUSTRIES

Pad. 13 stand D29

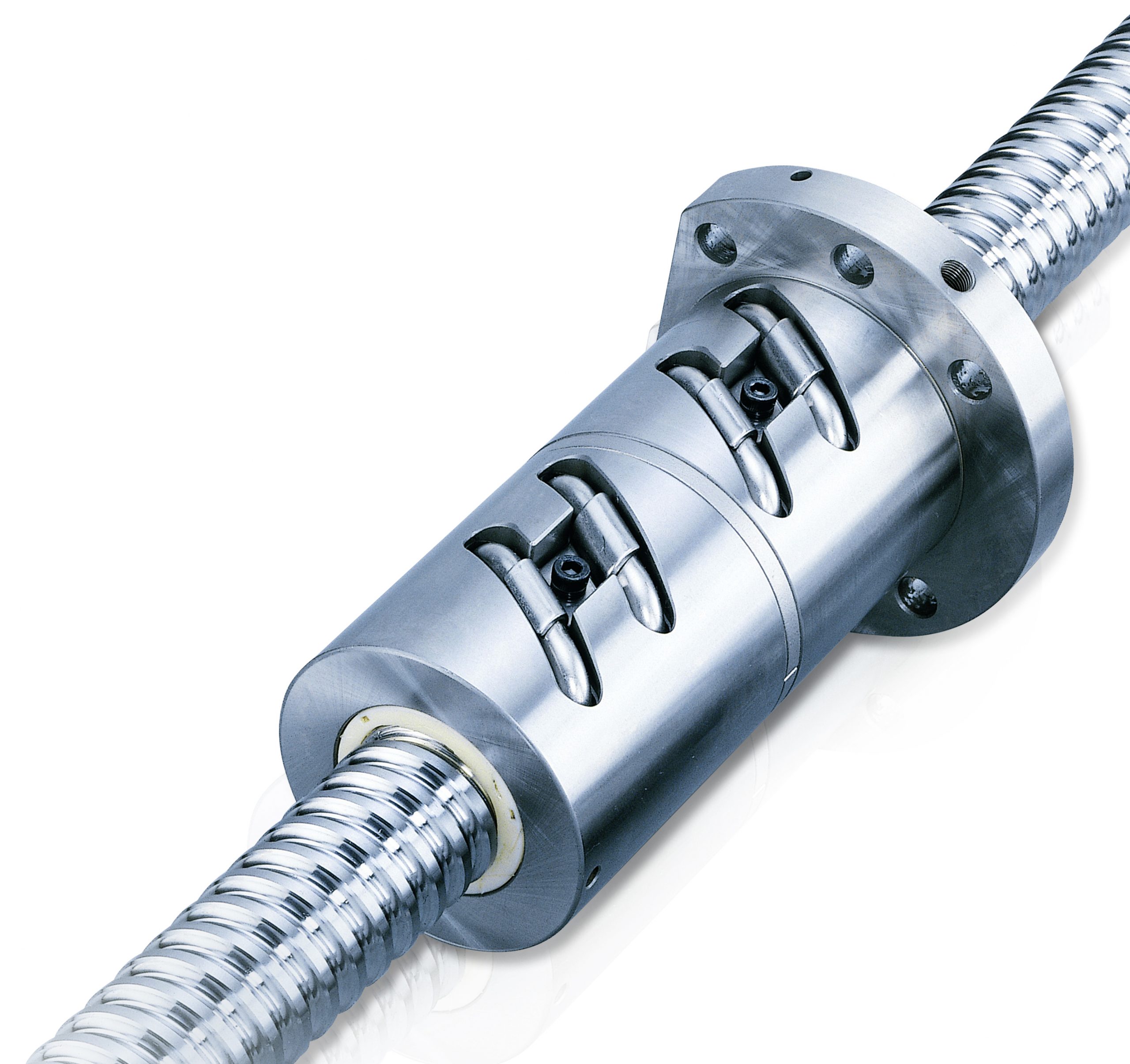

Ballscrews

Ballscrews

PMI has accumulated many years experience in production managing.

It covers the whole production sequence, from receiving the order, designing material preparation, machining, heat treating, grinding, assembling, inspection, packaging and delivery. The systemized managing ensures high reliability of PMI ballscrews. High working efficiency: Balls are rotating inside the ballscrews nut to offers high working efficiency. Comparing with the traditional ACME screws, which work by friction sliding between the nut and screw, the ballscrews needs only 1/3of driving torque.it is easy to transmit linear motion into rotation motion. No backlash and with high rigidity; The Gothic profile is applied by PMI ballscrews.

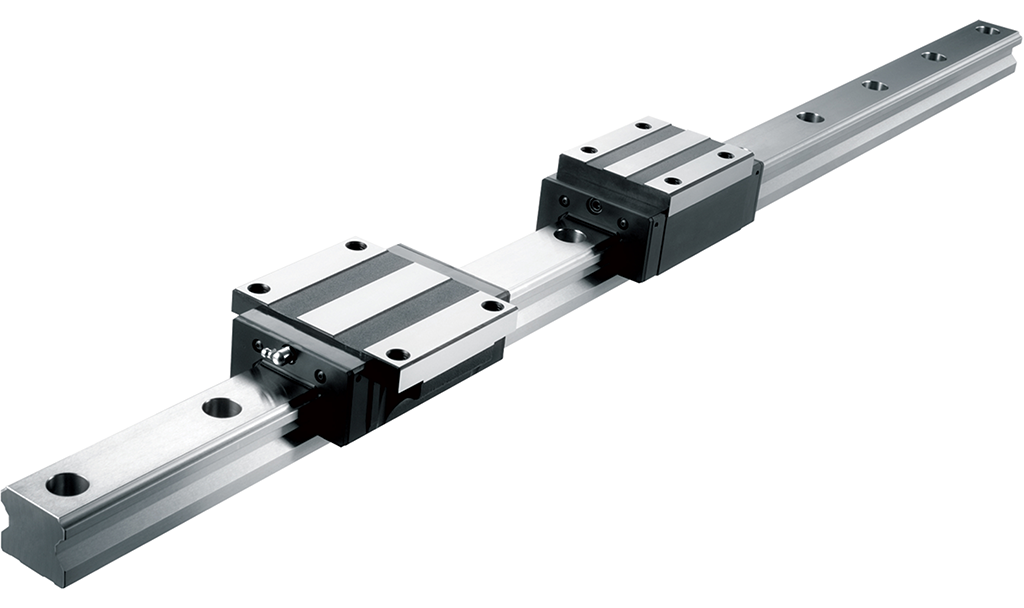

Linear guideway

High positioning accuracy, high repeatability;

The PMI linear guideway is a design of rolling motion with a low friction coefficient, and the difference between dynamic and static friction is very small. Therefore, the stick-slip will not occur when submicron feeding is making.

The optimum design of geometric mechanic makes the linear guideway to bear the load in all four directions, radial, reversed radial, and two lateral directions. Furthermore, the rigidity of linear guideway could be easily achieved by preloading carriage and by adding the number of carriages.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.