Software solutions: production 4.0 and transition 5.0

MECMATICA

Pad. 13 stand B48

For over twenty years MecMatica has been providing software to optimize, manage and monitor production, thanks to its strong experience and technical expertise, consolidated with more than 500 customers in the manufacturing sector. MecMatica products are part of the Metronomo.Net suite, the ERP (Enterprise Resource Planning) software born in production for production. The H24 connection and monitoring of more than 8,000 machine tools in Italy and worldwide is a tangible example of concreteness and effectiveness in the most diverse production realities, whether they are SMEs or large companies. The highly vertical expertise in the mechanical manufacturing sector enables the MecMatica team to always find the optimal solution for every need.

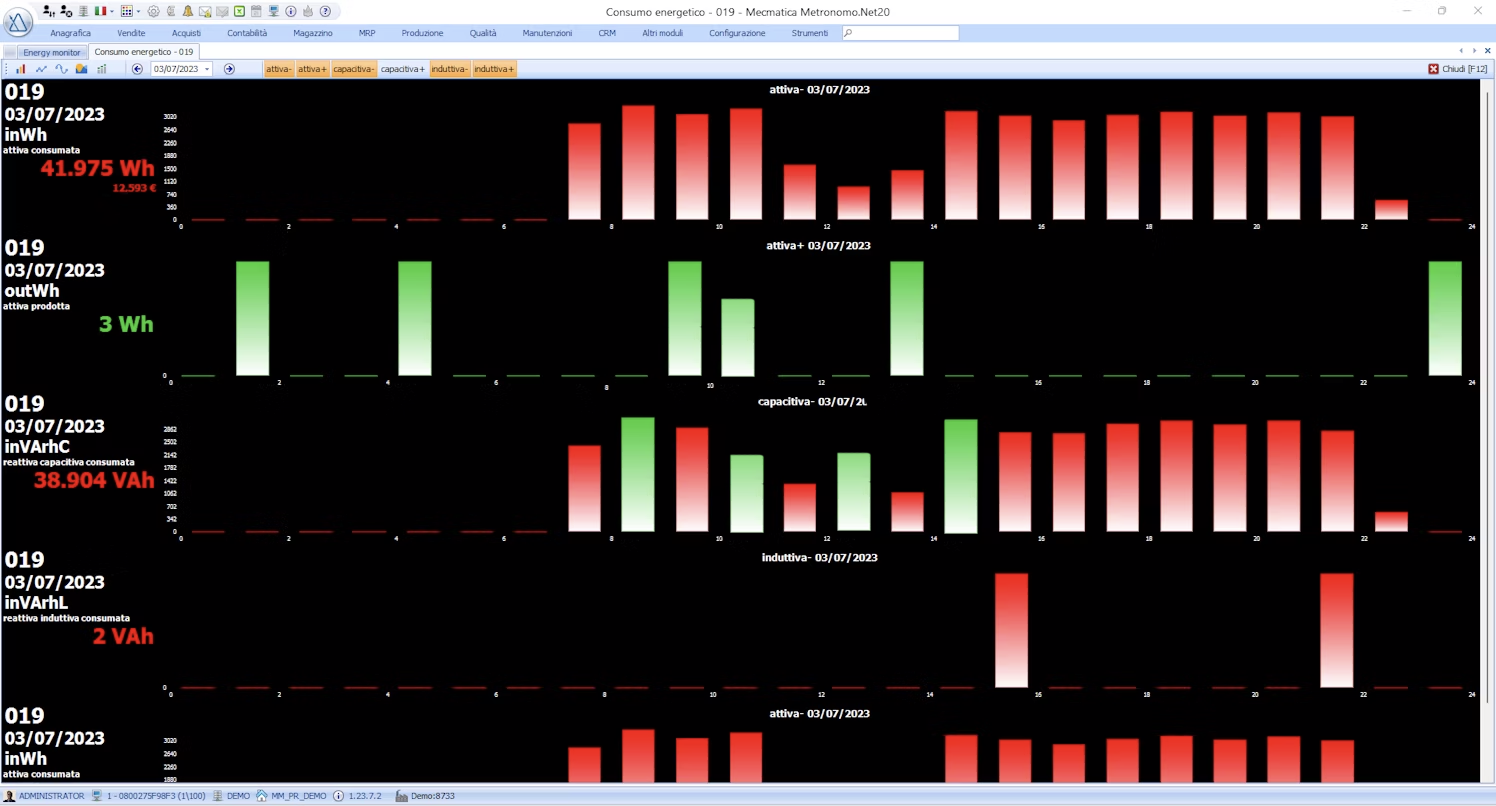

Metronomo.Net has accompanied companies in the world 4.0 and is ready to support them towards the Transition 5.0. The software consists of several modules that allow a perfect management of manufacturing companies. The modules of Metronomo.Net manage H24 monitoring of production resources (MES system), production planning, active and passive cycle, logistics, warehouses, quality, maintenance and much more. They work in synergy, allowing a complete control and now also green with Energy Monitor. Thanks to this new feature, MecMatica is able to monitor the energy consumption of production resources, a fundamental element for achieving certification of energy savings according to the green parameters of the 5.0 Transition Plan, for more sustainable production. Perfectly integrated with the Metronomo.Net suite, but also available in stand alone version, Energy Monitor allows you to always have under control the consumption of company resources through a Plug & Play system.

MecMatica is born from the union of mechanics and IT!

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.