New facing heads

O.M.G.

Pad. 11 stand E17

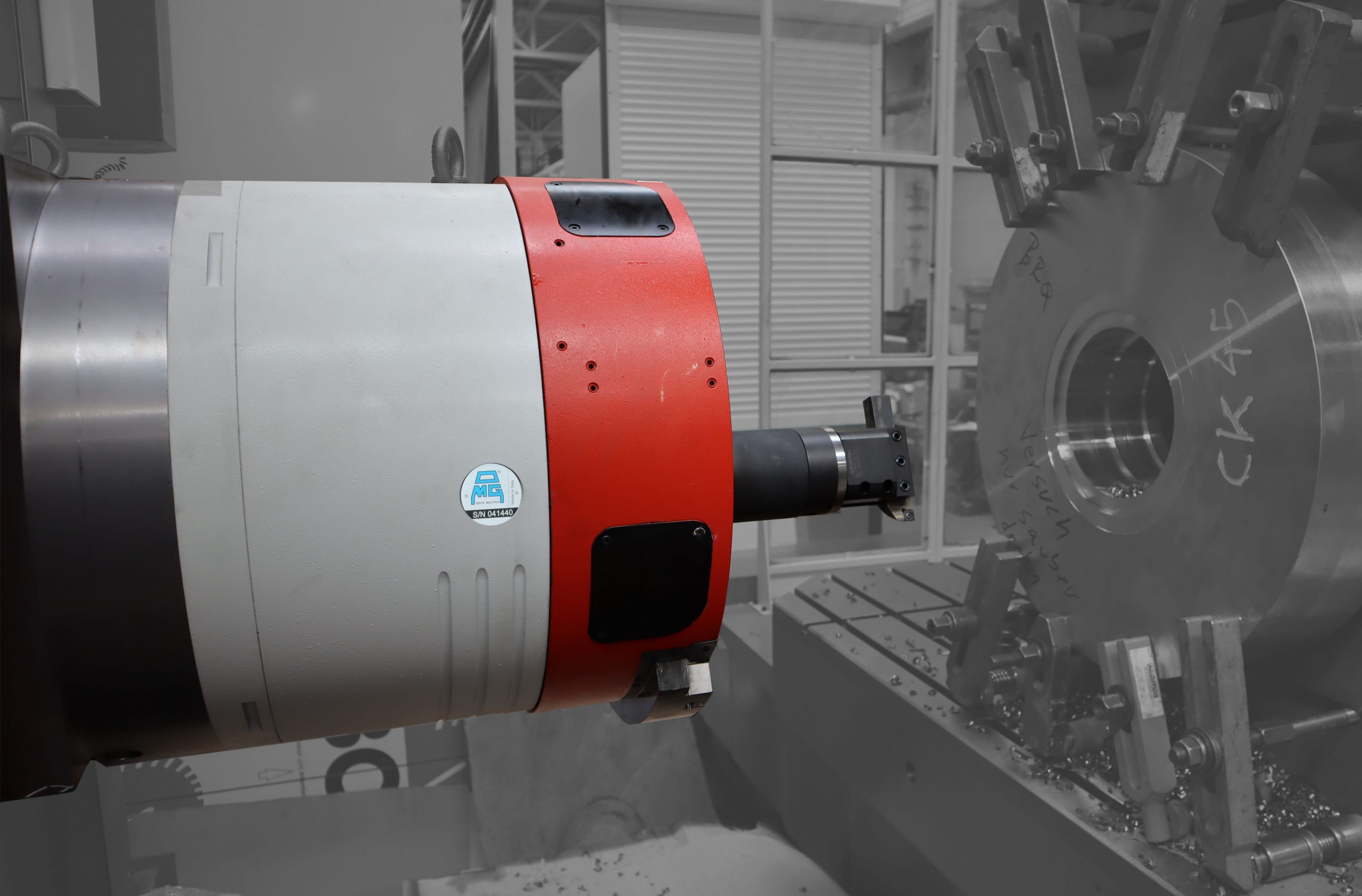

The challenge consisted in designing precise reliable heads, able to work also on machine tools with low spindle powers: the result is the new patented line of FH facing heads, with unique performances

indeed. This was enabled by a direct measuring device on the motion axis, the slide movement with motor and ball screw directly built in the rotating part and slide clamping system to increase accuracy in finishing operations.

The new facing heads of FH series, to be installed on NC machine tools, are prearranged for U controlled axis, they allow the execution of high-precision machining like external and internal facing, boring, cylindrical and conical threading and whatever interpolation with the axes of the machine tool. Facing heads can be mounted both manually and automatically, on any machining centre, more frequently on boring machines, vertical lathes or special machines. Produced in four different sizes, FH400, FH540, FH640 and FH800, heads provide 3:1, 4:1, 6:1 reduction ratio for the application also on machines with low spindle powers, assuring the necessary torque for the machining. Besides, three different sizes of the rotary part are available, according to end users’ needs, for each of the four sizes. However, what really distinguishes the product from competitors is the slide drive system, which is directly mounted on the rotary part instead of on the fixed one and, combined with the possibility of installing a direct position reading device, it allows utmost precision in machining phase. Moreover, the FH series can be supplied with hydraulic slide clamping system to achieve the highest precision and rigidity during the most demanding operations, the automatic greasing of the inner kinematics and of bearings, the radial or axial tool holder with manual or automatic CAPTO® change system, with prearrangement for Coromant Cutting Tools by Sandvik and the automated balancing.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.