The Evolution of Numerical Control with the New CNC1000 Series

BDF DIGITAL

Pad. 13 stand A22

In the world of industrial production, innovation is a fundamental element to remain competitive and meet the growing needs of customers. In this dynamic context, the introduction of the CNC1000 series represents a significant step forward in the evolution of numerical control, offering advanced and cutting-edge solutions for a wide range of industrial applications.

The CNC1000 series, developed by our leading company in the field of numerical controls, capitalizes on the commitments made in research, development, and technological innovation. Based on solid foundations (the CNC900 series, still in production), CNC1000 brings the numerical control experience to new levels of performance, versatility, and ergonomics.

The versatile and highly performing architecture characterizing the CNC 900 and 1000 series allows their use in various technological sectors: milling, turning, waterjet cutting, plasma cutting, oxy-fuel cutting, 2D/3D laser cutting, and sheet metal bending.

The hardware structure is modular and modern: based on EtherCAT bus, but available with other field buses, these CNCs can control local and remote drives and input/output interfaces.

All models are based on standard operating systems (Windows) and provide various connectivity technologies, ideal for Industry 4.0.

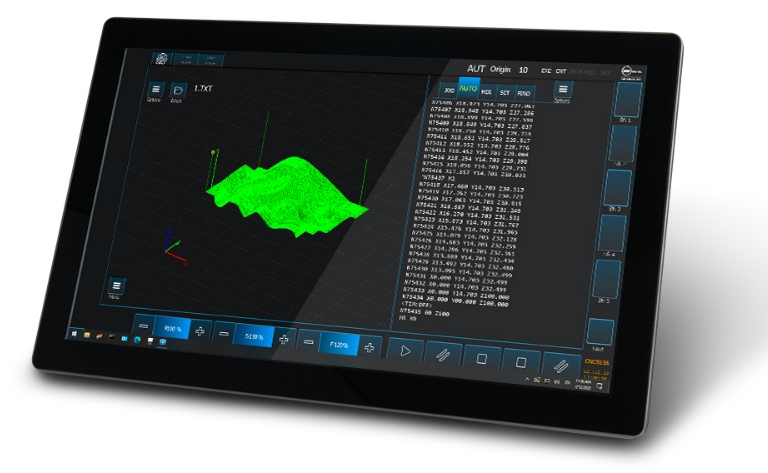

Among the main advantages of the CNC1000 series, there is undoubtedly its new Human-Machine Interface (HMI), designed with special attention to ergonomics and usability. This intuitive interface offers operators a smoother and more intuitive operational experience, reducing learning times, and maximizing operator productivity.

Another distinctive feature of the CNC1000 series is its compatibility with a wide range of screens, both with aspect ratios of 4:3 and 16:9. This flexibility allows operators to choose the type of screen that best suits their specific needs and machine configurations, further enhancing user experience and efficiency.

But the innovations of the CNC1000 series do not stop there. Thanks to its modular architecture and ease of upgrading, the CNC1000 is ideal for addressing the future challenges of industrial production. This flexibility allows companies to adapt quickly to new technologies and market trends, maintaining a leadership position in their sector.

In conclusion, the CNC1000 series represents a turning point in the evolution of industrial numerical control. With its advanced performance, the CNC1000 positions itself as the ideal choice for companies seeking to improve their production operations and remain competitive in an ever-evolving market.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.